Antiespumante de diseño especial para laminado de acero

- RISE

- Liaoning, China

- 7 días

- 50mt/Mes

* AÑADIR BASTANTE BAJO

* ANTIESPUMA RÁPIDA

* ANTIESPUMANTE LARGO

* RENDIMIENTO ESTABLE

* RESISTENCIA AL CORTE

STEEL ROLLING DEFOAMER

Causes of foaming in rolled steel

1. A variety of chemical additives are added during the production of steel plates, such as dispersants, accelerators, etc. Most of these additives are surfactants with foaming properties.

2. When the steel plate is cured, air or solvent is mixed between the layers in the gel coat layer, which easily leads to the generation of foam.

3. When the steel plate is immersed in water or affected by the moisture content in the air, the steel fiber is damp, resulting in foaming.

4. The temperature of the equipment in the production process of the steel plate is too high, so that the volatilization effect of the auxiliary agent is not good, resulting in the generation of foam.

Application of Steel rolling defoamer

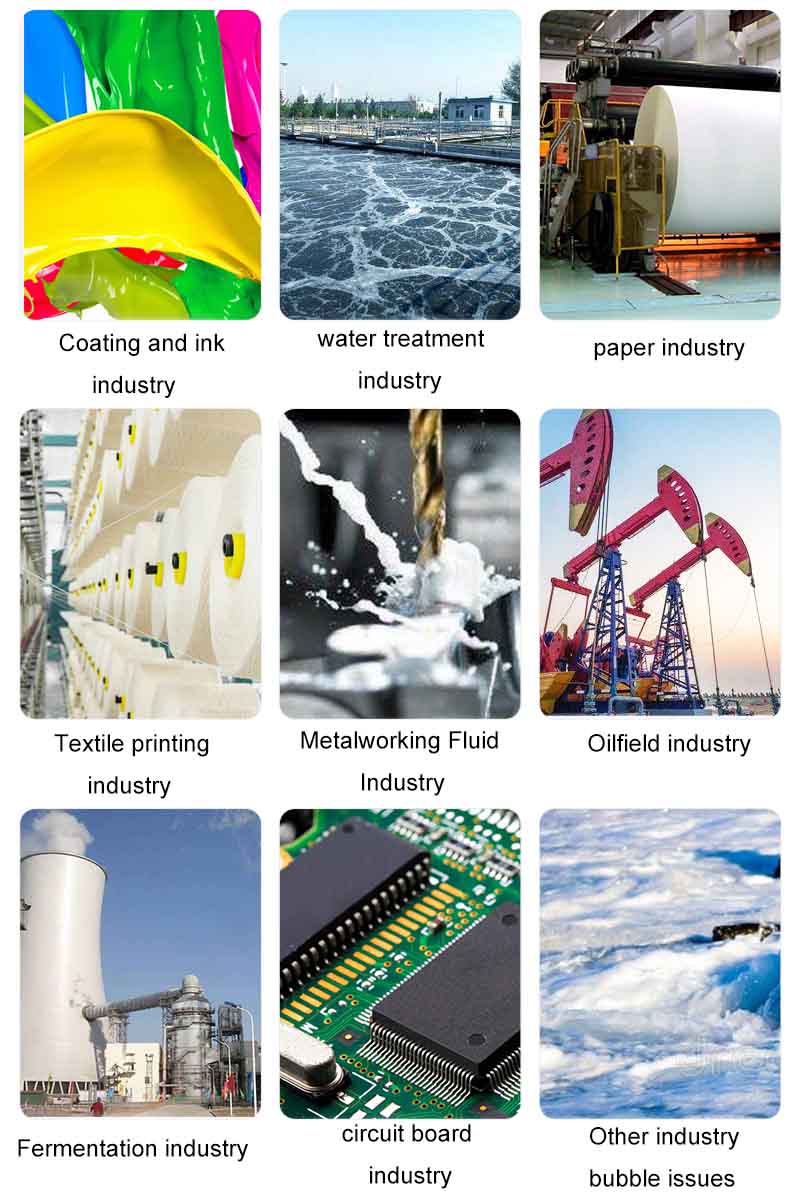

High temperature rolling steel defoamer is widely applicable to: steel plate cleaning agent, general cleaning under high pressure with strong acid and alkali, degreaser, metal cleaning polyether defoamer, degreasing powder cleaning agent, degreasing powder, alkaline degreasing powder for aluminum parts, general Coating cleaning, degreasing powder, degreasing agent, electroplating, stainless steel cleaning, high pressure spray cleaning, spray grease removal cleaning, industrial water treatment, chemical cleaning, etc.

Steel rolling defoamer introduction

The steel rolling defoamer specially developed, produced and sold by RISE defoamer manufacturer has the characteristics of fast defoaming and long defoaming, easy rinsing and no residue. And the addition amount is small, the factory sells directly, and the cost is saved. The high temperature rolling steel defoamer is very easy to disperse in water, can be well compatible with liquid products, and is not easy to break demulsification and leave oil. Our company will provide one-to-one technical services and solutions.

Steel rolling defoamer parameters

| Product name | High temperature rolling steel defoamer |

| EINECS No | 9006-65-9 |

| Model Number | AF707E |

| Purity | 50% |

| Brand Name | RISE |

| PH | 6.0-8.0 |

| Appearance | white emulsion /transparent liquid |

| Packing | 25kg 200kg 1000kg |

| Certification | ISO9001/ISO14001/45001 |

| Storage | 1 year |

Usage and Precautions for steel rolling defoamer

Addition Amount: The quantity of steel rolling defoamer to be added varies according to the different use systems. Usually, it can range from 0.05% to 0.3%, yet the actual amount is subject to determination based on specific operational conditions.

Packaging: The steel rolling defoamer comes packed in plastic drums with capacities of 25KG, 200KG, or 1000KG, providing options to meet diverse storage and usage needs.

Storage Conditions: Store the defoamer indoors in a cool, well - ventilated, and dry location. Ensure that the container is tightly sealed both before initial use and after each subsequent use. At around 25℃, it has a shelf life of 12 months.

Transportation Precautions: During transportation, the steel rolling defoamer must be properly sealed. This is to prevent any impurities like moisture, strong alkalis, strong acids, or rainwater from getting inside, as such contaminants could affect its quality.

Package

25kg, 200kg, 1 ton/ barrel available

Our advantage

With 20 years of experience and constant R&D, the technological expertise developed by RISE technical teams has resulted in an offer of silicone agents and processing aids capable of meeting a very wide variety of processing requirements.

From dedicated product development to on-site technical services, our people are always available to provide you with the best products and accurate application guidance.

We work closely with our customers on a case-by-case basis to develop and customize the right products for the right purposes. Much of our cooperation is based on long-term R&D partnerships, working together to steadily improve our materials to fit customer needs in fast-moving markets.

Send email to get free steel rolling defoamer sample

¡Sí! Somos una fábrica directa con I + D profesional y fabricante de antiespumantes desde 2004....more